Flow production is a widely adopted manufacturing method designed to produce high volumes of goods efficiently and consistently.

Central to this process is a coordinated system where a series of workers or machines are involved in creating a product in sequential stages. This coordinated structure is known as an assembly line.

In this article, we will explore the concept of the assembly line, how it functions within flow production, its historical roots, and its relevance in today’s modern manufacturing landscape.

This guide will also explain how tasks are divided, the effects of automation, and the pros and cons of using assembly lines in various industries.

What Is an Assembly Line and How Does It Work?

An assembly line is a manufacturing setup where products move through a series of workstations, each performing a specific task.

This linear progression ensures that each item is assembled step by step as it moves along the line, typically via a conveyor belt or similar transport mechanism.

The concept of the assembly line revolutionised industrial production by allowing tasks to be broken down into repeatable actions.

Henry Ford’s use of this method in the production of the Model T automobile is widely recognised as one of the earliest successful applications. His innovation dramatically cut production times and set a new standard in efficiency.

Modern assembly lines integrate advanced machinery and software to optimise the movement and handling of materials.

In highly automated environments, human workers may only be responsible for monitoring the process or handling specialised manual tasks.

Why Is the Assembly Line Crucial in Flow Production?

Flow production is designed to manufacture large quantities of identical products. The assembly line is integral to this method because it allows a constant and uninterrupted flow of work through each production stage.

Each component of the product is added in a fixed sequence, which ensures uniformity and predictable output.

This predictability is key in managing supply chains, forecasting production schedules, and maintaining consistent quality.

Without the structure of an assembly line, flow production would struggle to maintain the high volume and speed necessary for large-scale manufacturing. It also helps to:

- Minimise downtime between tasks

- Ensure consistent product specifications

- Reduce waste from manual handling or errors

Assembly lines ensure that the final product is completed quickly and with minimal variation from unit to unit.

How Are Tasks Divided Among Workers on an Assembly Line?

The division of labour is a defining characteristic of assembly line operations. Instead of a single worker constructing an entire product, each person is responsible for a particular task that contributes to the final item.

Tasks are assigned based on simplicity, time to complete, and skill requirements. This division enhances speed and reduces training time, as each worker only needs to master a single task or a limited set of tasks.

A simplified example of task division on an automotive assembly line might look like this:

| Workstation | Task Performed | Skill Level Required |

| Station 1 | Attach chassis to frame | Basic |

| Station 2 | Install engine components | Intermediate |

| Station 3 | Fit interior elements | Intermediate |

| Station 4 | Conduct electrical connections | Advanced |

| Station 5 | Final inspection and testing | Advanced |

This approach allows for a seamless flow of operations, with each stage preparing the product for the next. It also allows the employer to optimise labour costs by assigning more complex tasks to skilled workers and simpler tasks to entry-level staff.

What Types of Products Are Typically Made on an Assembly Line?

Assembly lines are best suited for industries where products are standardised and produced in large volumes.

The efficiency of this method is most evident when the same item is manufactured repeatedly over long periods.

Some of the common industries and product categories that utilise assembly lines include:

- Automotive manufacturing: cars, buses, and trucks

- Consumer electronics: smartphones, televisions, and laptops

- Household appliances: microwaves, washing machines, and air conditioners

- Packaged goods: ready meals, bottled beverages, and canned food

- Pharmaceuticals: medication blister packs and bottles

These products benefit from being produced using repetitive and predictable steps, which is ideal for the sequential nature of an assembly line.

How Has Automation Changed Modern Assembly Lines?

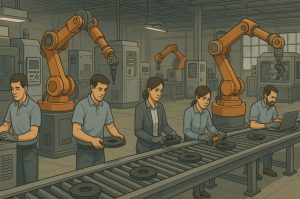

The evolution of technology has significantly altered how assembly lines operate. What once relied heavily on manual labour has now shifted towards machine-led processes driven by robotics, sensors, and artificial intelligence.

Modern assembly lines use a combination of:

- Conveyor systems that move products at a consistent speed

- Robotic arms programmed to handle complex or repetitive tasks

- Cameras and sensors that perform real-time quality inspections

Automation has led to increased production rates and reduced human error. It also enables companies to monitor every detail of the manufacturing process with data-driven insights.

However, automation introduces new challenges. Workers must now be trained to operate and maintain machines.

The initial investment for automated systems is also significant, although the long-term savings can outweigh the costs.

To illustrate the contrast between traditional and modern assembly lines:

| Feature | Traditional Assembly Line | Modern Automated Line |

| Labour involvement | High | Moderate to low |

| Speed of production | Moderate | High |

| Error rate | Higher | Lower (with automation) |

| Flexibility in production | Low | Moderate (with programming) |

| Initial setup cost | Lower | Higher |

Despite these differences, the core principle remains the same—moving a product through various stages of assembly until it is completed.

What Are the Advantages and Disadvantages of Assembly Line Production?

Assembly line production offers clear benefits in terms of efficiency, cost, and scalability, but it also has drawbacks, particularly for workers and in situations that require production flexibility.

Advantages:

- Enables the production of large volumes at a consistent quality

- Reduces per-unit production cost through economies of scale

- Allows for specialisation, which increases productivity

- Simplifies the training process for new workers

- Supports integration with automation for greater efficiency

Disadvantages:

- Repetitive tasks can lead to worker fatigue or injury

- Difficulty in adapting to custom or short-run production

- High setup costs for machinery and infrastructure

- Over-reliance on the smooth functioning of every part of the line

- Limited job variation, potentially reducing employee satisfaction

For companies operating in dynamic markets, this rigidity can be a constraint. However, businesses producing standardised products benefit greatly from the streamlined workflow provided by an assembly line.

How Do Companies Maintain Efficiency on an Assembly Line?

Maintaining efficiency on an assembly line is vital for sustaining high output, meeting production targets, and ensuring profitability.

When even a single workstation underperforms or halts, it can lead to significant delays, increased costs, and quality issues across the entire production process.

For this reason, companies employ a range of strategic and operational measures to optimise every aspect of assembly line performance.

Line Balancing for Even Workflow

One of the most fundamental techniques used in assembly line management is line balancing. This involves allocating tasks across workstations in a way that ensures each station completes its activity in the same cycle time. If one task takes longer than the others, it creates a bottleneck, leading to idle time at other stations and disrupting the continuous flow.

Companies conduct time and motion studies to understand how long each task takes and adjust the distribution of work accordingly. In cases where a specific task is too complex or time-consuming, it might be split across multiple stations or assigned to more skilled personnel.

Key outcomes of effective line balancing include:

- Reduction in production delays

- Improved worker utilisation

- Smoother operational flow across the entire line

Preventive Maintenance and Equipment Reliability

Efficiency heavily depends on the consistent performance of machinery. Unplanned downtime due to mechanical failure can bring an entire assembly line to a standstill. To mitigate this risk, companies implement preventive maintenance schedules, which include regular inspections, lubrication, part replacements, and software updates.

Predictive maintenance technologies, such as IoT sensors and machine learning algorithms, are also increasingly used to forecast equipment failures before they occur. These systems alert engineers to anomalies such as unusual vibrations, overheating, or wear and tear, enabling timely intervention without interrupting the workflow.

Maintaining equipment reliability is essential to:

- Avoid costly downtime

- Extend the lifespan of machinery

- Ensure safety for line workers

Quality Control Integration

In an efficient assembly line, quality control is not isolated to the final inspection phase. Instead, it is embedded at multiple points throughout the production process. This approach, often referred to as in-line quality control, ensures that defects are identified and corrected at the earliest possible stage.

Techniques include:

- Visual inspections performed by operators

- Digital sensors that measure dimensions, weight, or electrical signals

- Automatic rejection systems that remove faulty items from the line

By catching defects early, companies prevent defective units from progressing further down the line, saving time and reducing waste. This also contributes to a higher overall yield of saleable products.

Workforce Training and Task Standardisation

Human workers still play an essential role in many assembly line operations, particularly in sectors where manual dexterity or decision-making is required. To maintain efficiency, companies invest in regular training programmes that ensure workers are up to date with safety procedures, task instructions, and equipment operation.

Standard operating procedures (SOPs) are created to define each task clearly. These SOPs minimise variability and ensure that tasks are performed uniformly across shifts and teams.

Some training and standardisation practices include:

- Instructional videos for onboarding new staff

- On-the-job coaching and peer mentoring

- Periodic assessments and performance reviews

Training supports not just productivity but also worker morale, reducing the likelihood of errors caused by confusion or inconsistency.

Real-Time Monitoring and Production Analytics

To make data-driven decisions, many manufacturers use real-time monitoring systems that track key performance indicators (KPIs) such as output rate, cycle time, downtime, and defect rates. These systems collect data from machines and workstations and present it via dashboards accessible to supervisors and managers.

By having a live view of what is happening on the line, management can identify inefficiencies quickly and make adjustments as needed. For example, if one workstation consistently lags behind, it may signal the need for re-training, reallocation of tasks, or technical intervention.

Benefits of real-time analytics include:

- Fast response to issues before they escalate

- Enhanced productivity tracking

- Better planning for inventory and workforce needs

How Does the Assembly Line Model Influence Business Operations Today?

The principles behind assembly lines extend beyond manufacturing and are applied in many other areas of business. In logistics, warehousing, and even service-based industries, the idea of streamlining tasks into a logical, sequential process is used to improve productivity.

In the UK, many industries still rely on assembly lines as the backbone of their operations, especially in automotive manufacturing hubs such as the Midlands and the North East. The structure enables British firms to compete in international markets by producing goods at competitive prices while meeting strict quality standards.

The influence of the assembly line can also be seen in startup environments, particularly those involved in hardware production. These businesses may begin with manual processes but often transition into semi-automated lines as they scale.

As the global market continues to prioritise speed and efficiency, the assembly line model remains a foundational element of modern business operations, evolving to meet new demands through smart technology and data-driven improvements.

Conclusion

The term used to describe a series of workers working on products in flow production is the assembly line. This method is central to the concept of mass production and has transformed industries by enabling high-volume, efficient, and standardised manufacturing.

While it has evolved over time with the integration of automation and digital tools, the core principle remains: dividing the production process into manageable, repeatable tasks performed in a linear sequence. Understanding how assembly lines function provides valuable insights into both past and present manufacturing strategies—and how businesses can innovate for the future.

Frequently Asked Questions (FAQ)

What is the difference between a production line and an assembly line?

A production line refers broadly to the entire sequence of operations involved in manufacturing a product. An assembly line is a specific type of production line where each worker or machine performs a specific task in sequence.

Can flow production work without an assembly line?

Flow production is typically dependent on an assembly line or a similar structured setup. While automation or modular designs can modify the traditional model, the principle of continuous workflow remains key.

How do companies ensure quality on an assembly line?

Quality is maintained through real-time monitoring, automated inspection systems, regular maintenance, and staff training. Many companies also follow strict quality standards like ISO certifications.

What skills are needed to work on an assembly line?

Key skills include attention to detail, manual dexterity, ability to work under time constraints, teamwork, and in some cases, basic technical knowledge of machinery or tools.

Are assembly lines still used in the UK today?

Yes, many industries in the UK, especially automotive, food production, and electronics, still use assembly lines for mass production. Automation has enhanced many of these systems in recent years.

How did Henry Ford change the manufacturing industry?

Henry Ford introduced the moving assembly line in 1913, significantly reducing production time and costs. This innovation made mass production feasible and changed the global manufacturing landscape.

What is line balancing in manufacturing?

Line balancing is the process of ensuring each workstation on an assembly line takes the same amount of time to complete its task. It minimises delays and improves efficiency.